EN 388

Mechanical Risk

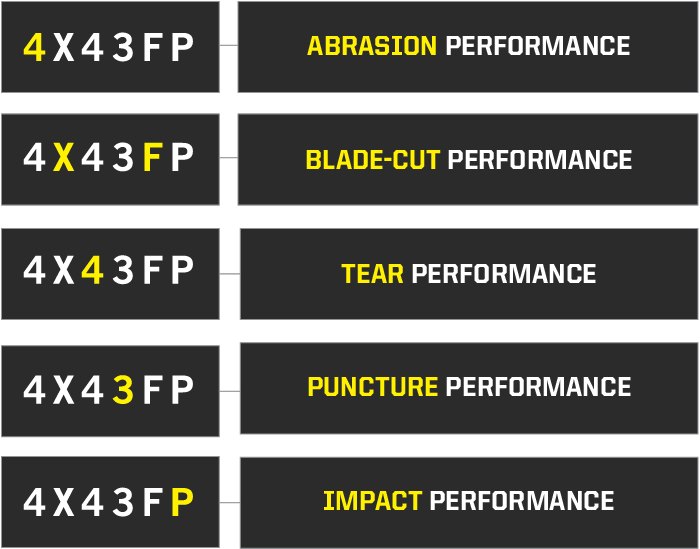

When it comes to work gloves for mechanical risks, CE standard EN 388 measures overall performance against abrasion, cut, tear, puncture, and impact injuries.

ABRASION PERFORMANCE

4X43FP

Performance Levels 0–4

The abrasion test is performed as the rubbing heads move in an elliptical motion, and the number of cycles required to abrade through the material is recorded. The advertised performance level is the lowest recorded result of 4 complete material tests.

BLADE-CUT PERFORMANCE

4X43FP

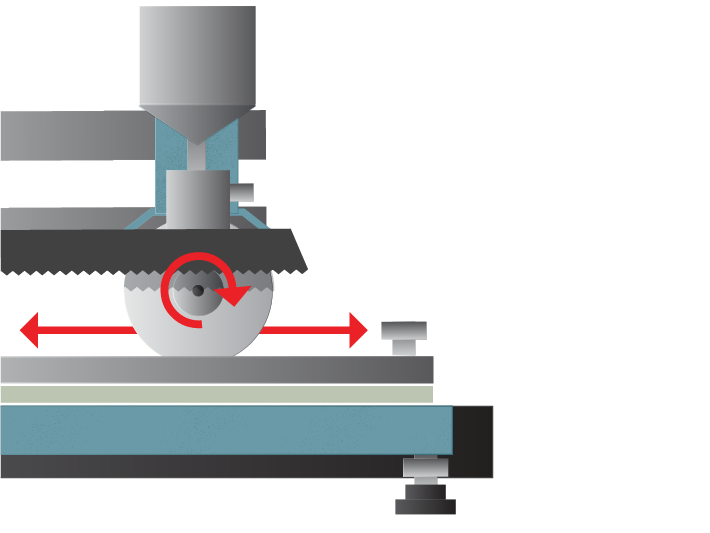

COUPE TEST

The Coupe Test uses a circular blade to produce a 1-5 performance rating, but has its limitations when it comes to high-cut composite/aramid fiber material and metal blends, which can cause Coupe Test blades to dull and produce false readings. The circular blade test uses a rotating blade under 5N of contact force that tracks backwards and forwards across the surface of the test material. The number of strokes is recorded until the blade cuts through the test material.

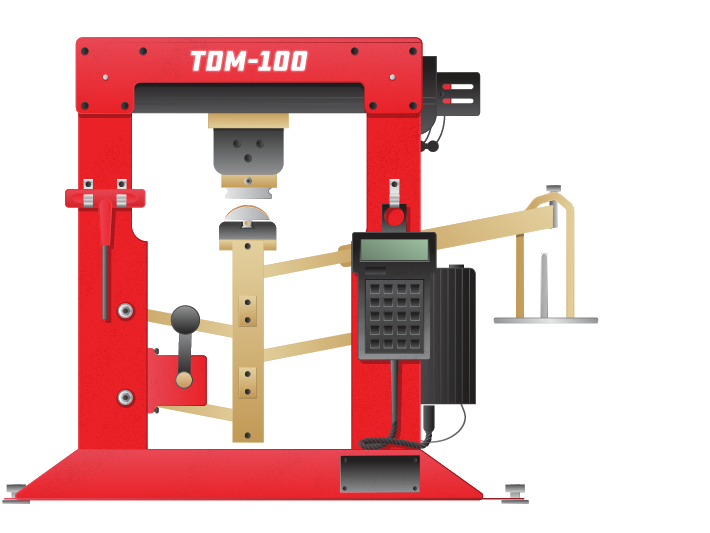

TDM TEST

The TDM straight blade travels once across the test material and is only used once. TDM Test rates materials on a scale of A - F and uses an oscillating blade that measures the force necessary to cut through high-cut materials. Materials that test beyond Level 3 or produce a false Coupe Test reading will receive an "X", and the TDM Test is introduced where a letter rating A - F is determined (Example 4X43FP). If the TDM Test isn't required, an "X" is used to state that there's no rating (Example 4243XP).

TEAR PERFORMANCE

4X43FP

Performance Levels 0–4

Tear resistance is measured with a standard tensile strength machine using pre-cut palm material from four glove samples. The jaws of the machine are fitted with the sample material and tear resistance is measured as the jaws move apart at a constant rate of speed (100mm/min). The force needed to tear the material is recorded and the lowest result of four tests is advertised.

The jaws of the machine are fitted with the sample material and tear resistance is measured as the jaws move apart at a constant rate of speed. The force needed to tear the material is recorded and the lowest result of four tests is advertised.

PUNCTURE PERFORMANCE

4X43FP

Performance Levels 0–4

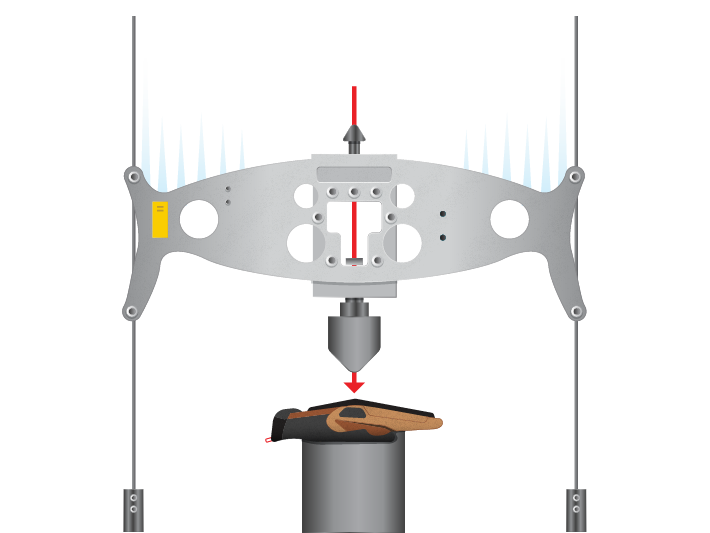

Puncture resistance is measured using a rounded stylus, which is pushed 50mm at constant speed of 100mm/min using a compression test machine. The amount of force needed to puncture the material is recorded and the lowest result of 4 tests is advertised.

IMPACT PERFORMANCE

4X43FP

Pass / Fail