EN 511: 2006 Testing Standards for Winter Gloves

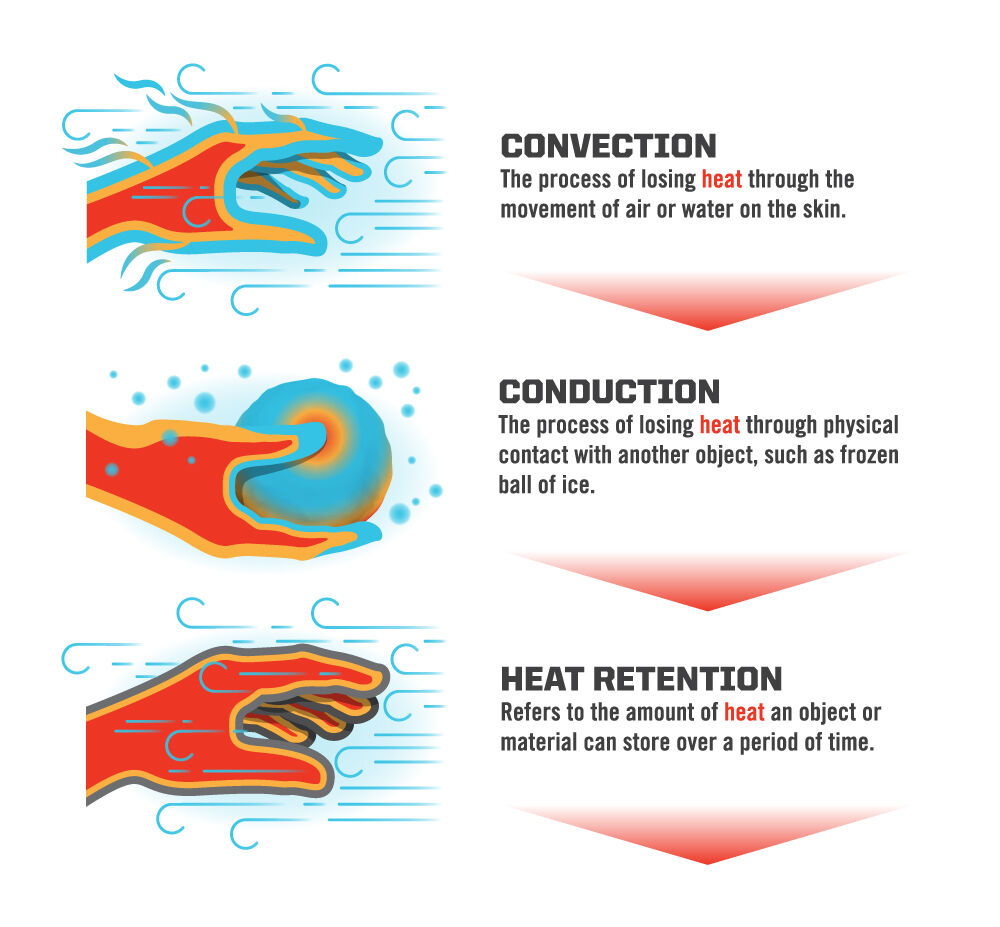

Air temperature, wind speed, and moisture present major challenges for working hands in cold environments. In order to counterbalance these factors, it’s important to have properly rated outerwear for any given work environment. When it comes to choosing the right set of specialty cold weather work gloves or traditional winter gloves, it’s important to understand how cold weather gloves are tested and rated for use.

Heat retention is critical in cold working environments especially with prolonged exposure to the elements, but not just any cold weather glove will do. The blood in your body is sensitive to temperature changes of as little as .5 degrees Celsius! So, evaluating the type of work and severity of weather in your region will help determine the level of protection you need.

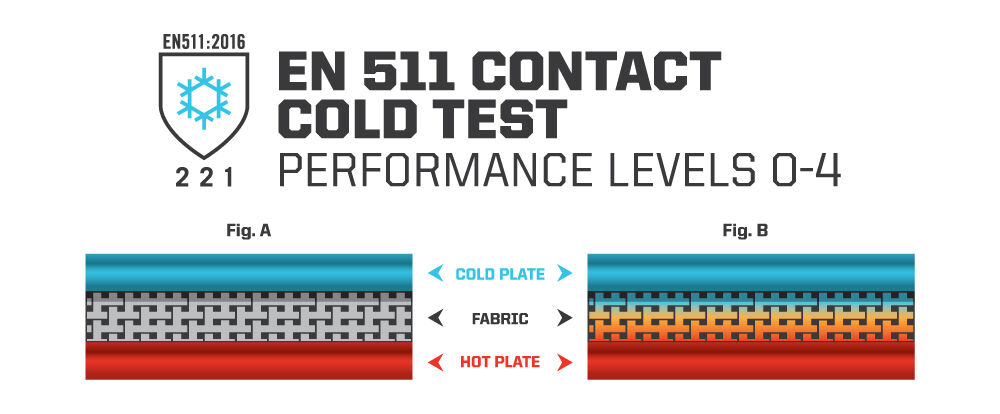

CE European Glove Standard EN 511: 2006 specifies the requirements and test methods for gloves which protect against convective and conductive cold down to -50 °C. This cold can be linked to the climatic conditions or an industrial activity. The specific value of the different performance levels are decided by the special requirements for each class of risk or the special areas of application. Don't worry, we break it all down in our EN 511: 2006 infographic.

When the mercury drop we struggle to retain heat. The skin appears bloodless, our muscles shiver to create heat and the potential for frostbite threatens fingers, ears, and toes. Cold environments are a challenge for working hans due to multiple contributing factors to heat loss. CE standard EN 511: 2006 is designed to measure the performance of cold weather hand protection so you're one step ahead of the cold.

Heat retention is crucial in cold work environments in order to prevent cold weather injuries. To counterbalance these factors, it's important to have properly rated outerwear for any given environment. EN 511: 2006 ratings for cold weather gloves are measured by the following CE testing procedures:

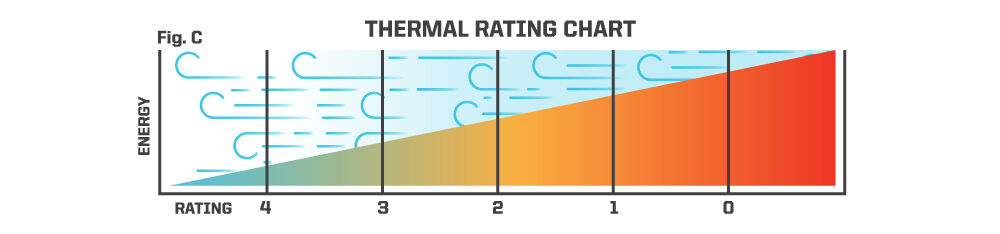

The glove sample is place on an electrically heated mannequin hand (Fig. A) that measures the amount of power required to maintain 30°C and 35°C in a controlled environmental chamber. The chamber is cooled down to 20°C below that of the heated hand, and constant air flow is applied (Fig. B). The more electrical power required, the lower the thermal insulation rating of the glove (Fig. C).

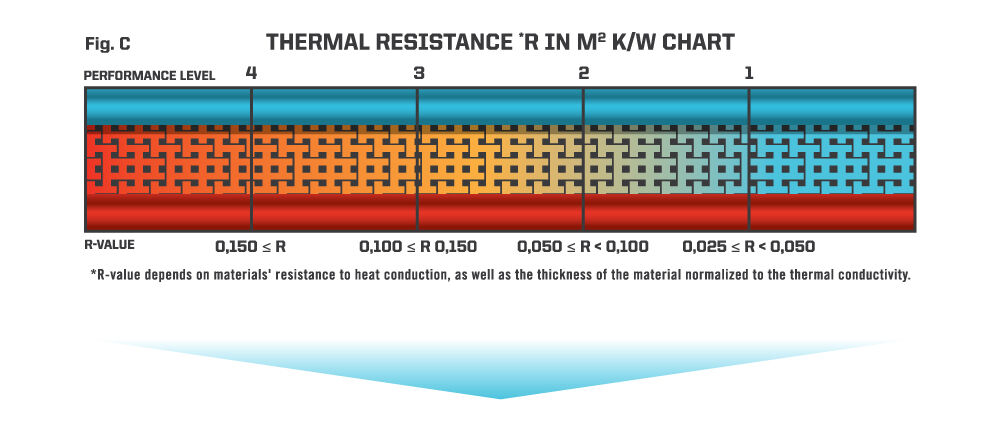

The glove sample is placed between metal plates which are at different temperatures (Fig. A) in order to measure the temperature drop (Fig. B), also knows as thermal resistance.

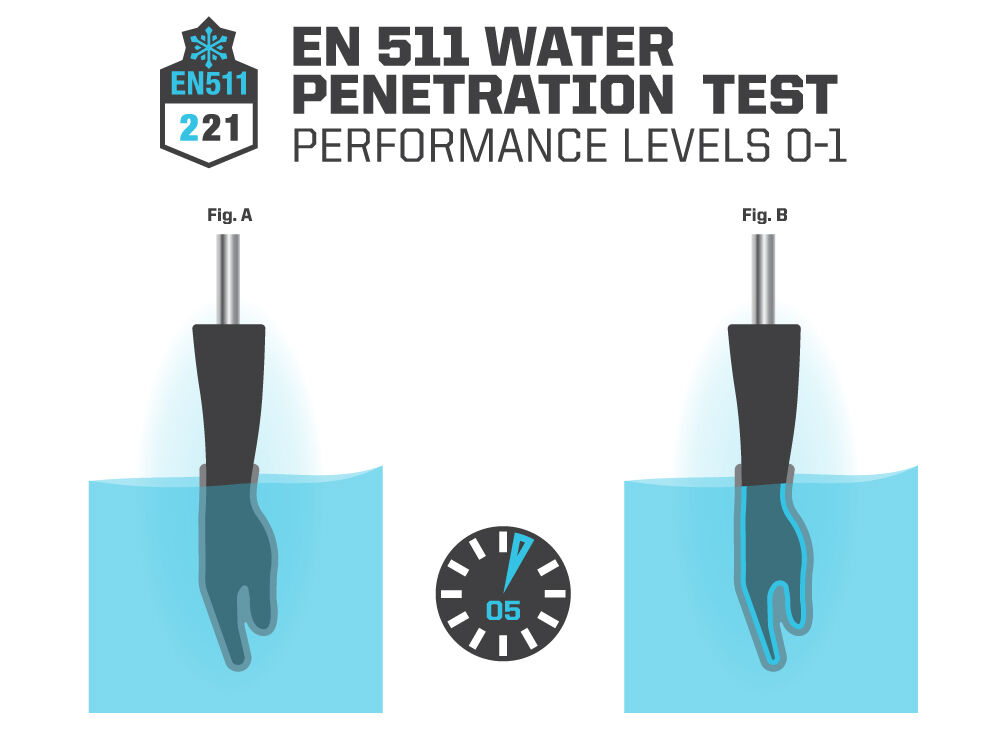

The glove sample is fully submerged in water for 5 minutes to measure its permeability (Fig. A). If the glove maintains impermeability for the 5 minute duration, it will receive a Level 1 "Pass Rating". If the glove takes on water during the 5 minute duration, it will receive a Level 0 "Fail" rating (Fig. B).